Add to Cart

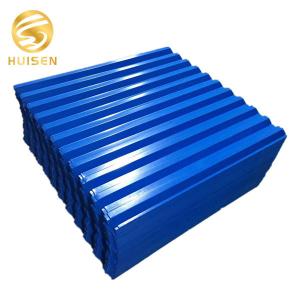

Blue PVC Inclined Pipe Packing Lamella Tube Settler For Clarifier Tank

Inclined pipe is mainly used for sedimentation and desanding. It is the most widely used and mature water treatment device in water supply and drainage engineering in more than ten years. It has the advantages of wide application range, high treatment effect and small floor area. It is suitable for desanding at water inlet, settling, oil separation and tailings concentration treatment of general industrial and domestic water supply. It is suitable for both new construction and reconstruction of existing old pool, and can achieve good economic benefits

1. The treatment efficiency is higher than that of the activated sludge process. The general hydraulic load is 100-200m3 / m2 / day, and the organic load is 2000-5000g / m3, so the occupied area is reduced.

2. The aeration intensity is lower than that of the activated sludge method, and there is no need for sludge return, so it can reduce power consumption and simplify management.

3. The amount of sludge is small, which reduces the workload of post-treatment such as sludge dewatering.

4. The sludge produced has good sedimentation, which is conducive to the removal of suspended solids in the later stage.

5. It has strong adaptability, can adapt to a wide range of different water quality, has strong endurance to the impact load of water quality and water quantity mutation, and maintains stable treatment effect.

6. As long as the scientific operation management is carried out and the sewage is flushed regularly, the blockage will not be caused generally.

Technology Parameter

| Material | Dimension(mm) | Color | Thickness(mm) | Specific surface area(m2/m3) | Porosity(m2/m3) |

| PP | Dn35 | White | 0.4 | 169.4159 | 0.957 |

| Dn50 | 0.5 | 119.0055 | 0.9739 | ||

| Dn80 | 0.8 | 99.3071 | 0.9481 | ||

| PVC | Dn35 | Black or Blue | 0.4 | 236.0987 | 0.9487 |

| Dn50 | 0.5 | 119.0055 | 0.9799 | ||

| Dn80 | 0.8 | 99.3071 | 0.6781 |

Installation procedure

1. Installation of sludge discharge pipe at the bottom of inclined pipe sedimentation tank the installation sequence of inclined pipe sedimentation tank generally starts from the bottom, and the installation of sludge discharge pipe system at the bottom is completed first to ensure that the opening of sludge discharge pipe meets the design requirements, is fixed firmly, and is not allowed to enter the next installation sequence until it is checked to be correct. A kind of

2. Complete the packing support installation of inclined pipe according to the packing support installation construction drawing of inclined pipe sedimentation tank, first install the packing support in place, check that all welding joints are firm, the support strength is enough to bear the packing weight, and complete the anti-corrosion treatment on the support surface;

3. Complete the hot joining of inclined pipe packing according to the hot joining method of inclined pipe packing, each packing of inclined pipe packing shall be treated as a separate hot joining unit, which is 1m2 after the hot joining of one unit. After the hot joining, it shall be stacked orderly on the site (a small amount of loose pieces shall be reserved for standby). A kind of

4. Assembly in inclined tube packing tank assemble the pressed packing unit on the upper part of the packing support from left to right. Keep the angle of 60 ° unchanged all the time. Each unit shall be properly pressed during assembly in sequence. If the size is not right when assembling to the right side, it is necessary to use a piece of oblique tube packing according to the size to iron and connect until all are in place.

5. The upper part of the inclined pipe packing is fixed because the proportion of the inclined pipe packing is 0.92, which is slightly less than water, the inclined pipe packing needs to be pulled from left to right above the packing after it is assembled in the tank The round steel of 10 mm shall be reinforced (two round steels are required to pass the upper part of each unit filler). Both ends of the round steel shall be reliably fixed on the wall of the sedimentation tank. After the installation of the round steel, it can well prevent the possible loosening and floating of the inclined pipe filler in the initial use. The round steel shall be corrosion-resistant with coal tar epoxy asphalt.